- Hava tankı üstü vidalı kompresör

- Sabit Vidalı Kompresör

- İnvertörlü vidalı kompresör

▪ Pistonlu Kompresörler

- Pistonlu kompresör

- Şaseli kompresör

- Tek kademeli kompresör

- Çift kademeli kompresör

- Kafa ve şaseler

Basınçlı hava elde etmek amacı ile kullanılan kompresör çeşitdir. Başka kompresör çeşitlerine göre bir piston ya da benzeri bir donanım kullanılamaz. Farklı olarak, birbirine geçmiş rotor çifti kullanılır.

Haberin devamı için tıklayınız

Kompresör kelimesinin tüm dillerde ki sözlük anlamı nedir? Kompresör kelimesinin tüm dillerde cümle/metin çevirisi, yazılışı ve okunuşu aşağıda bulunan tabloda mevcuttur.

Haberin devamı için tıklayınız

Kompresör, Fransızca kökenli bir bulgudur. Fransızca adı; Compresseur 'dir. Kompresör, Gaz Kompresörü olarak da anılır.

Haberin devamı için tıklayınızHankinson Kurutucu

CALYPSO Basınçlı Hava Kurutucuları

Hankison HHD Series Refrigerated Air Dryers Improve Productivity

Since 1948, people around the globe have relied on Hankison to deliver the right solutions to efficiently meet the needs of today’s applications for compressed air treatment. HHD Series non-cycling refrigerated compressed air dryers offer the right combination of technology and simplicity to keep your air system at a dry +3°C pressure dew point, from 20 through 800 m3/h.

Gain Efficiency

Air-powered products and processes operate best with clean and dry compressed air. Productivity improves. Rejects decrease. Maintenance personnel are able to be proactive and work from their schedule. The entire facility runs smoothly and contributes to financial stability and competitiveness.

Built-in Durability and Reliability

All HHD Series dryers are built for durability, in a space-saving design. Sturdy sheet steel is formed and protected by an epoxy-based powder coat finish. Reliable reciprocating refrigeration systems use environmentally friendly R-134a refrigerant. R-134a is known for its ability to maintain stable temperatures to protect the integrity of the +3°C pressure dew point. HHD Series can handle the pressure.

Dry Compressed Air – Pure & Simple

Research indicates that many customers want reliability and dry compressed air at an affordable price. No fancy bells and whistles – just dry air, pure and simple. The HHD Series non-cycling dryers were designed to meet these demands.

Models HHD 21 through HHD 101

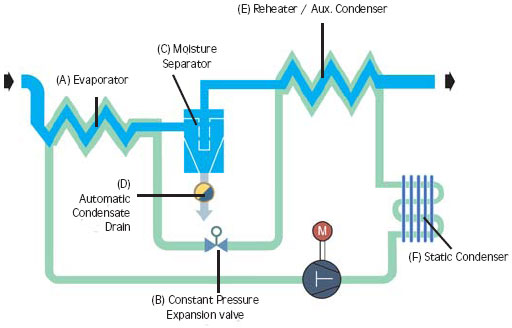

Warm saturated air enters the Evaporator (A) where it is cooled by refrigerant being controlled by a Constant Pressure Expansion Valve (B). Water vapor condenses into a liquid for removal at the moisture separator (C) by an Automatic Drain (D). The cold, dry air is reheated as it passes through the Reheater (E). This prevents pipeline sweating. The Static Condenser (F) eliminates the need for a cooling fan and simplifies the system.

Models HHD 151 through HHD 800

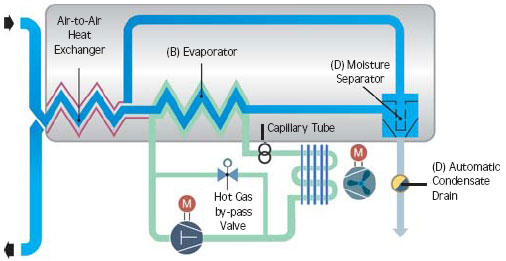

Warm saturated air enters the air-to-air heat exchanger (A) where it is precooled by the outgoing chilled air, and then passes through the air-to-refrigerant (evaporator) heat exchanger (B) where it is further cooled by the refrigeration system. Water vapor condenses into liquid droplets to be removed by the Moisture Separator (C) then, discharged from the dryer by an automatic drain (D). Chilled dry air returns through the air-to-air heat exchanger (A) where it is reheated before exiting the dryer.

HHD Series – Standard Features

Easy to install package saves time. Simply connect the pipes and plug in the power cord.

• Adapts to system needs without complicated controls. Fully automatic operation saves money.

• Every unit comes pre-assembled with quality components. Long service life.

• Steady +3°C pressure dew point. Ensures maximum moisture removal every day.

• On/off switch illuminates when compressor is on

• At-a-glance control panel dew point indication verifies performance (HHD 31 – HHD 800)

HHD Series – Models through 100 m3/h

• Static condenser recycles waste heat to eliminate cold, sweaty pipes

• Integral Moisture Separator

• Timer operated drain with isolation valve/strainer (float drain on HHD 21)

• On/off switch illuminates when compressor is on

HHD Series – Models 150 to 800 m3/h

• Integral 304 stainless steel heat exchanger, mesh demister and, moisture separator for long life

• Timer operated drain includes isolation valve/strainer to protect valve from rust and scale

• Panel mounted drain timer controls (HHD 400 – 800)

• LED style dew point indicator (HHD 400 – 800)

• Panel filter captures ambient dirt and dust to keep condenser clean

COLDWAVE™ REFRIGERATED COMPRESSED AIR DRYERS

HHDp & HDS Series

Hankison ColdWave™ refrigerated dryers feature our most advanced heat exchanger technology. Being the global leader in compressed air treatment is what continues to set the Hankison brand apart. Since L.E. Hankison patented the Condensifilter™, (forerunner to the refrigerated air dryer) in 1943, Hankison engineers have set the industry standard for refrigerated dryer technology. ColdWave™ heralds the next generation of Hankison high performance refrigerated dryers designed for quality and reliability.

COLDWAVE DRYERS REDUCE OPERATING COSTS

Manufacturing Energy Efficient Solutions.

For more than half-a-century, Hankison quality, performance and reliability set the standard for global compressed air treatment products. The tradition continues. Industry leading ColdWave™ Technology infuses the latest generation of refrigerated dryers with rugged durability, energyefficiency and long service life. It’s no wonder that leaders of industry specify Hankison products to protect their critical products and processes from contaminants.

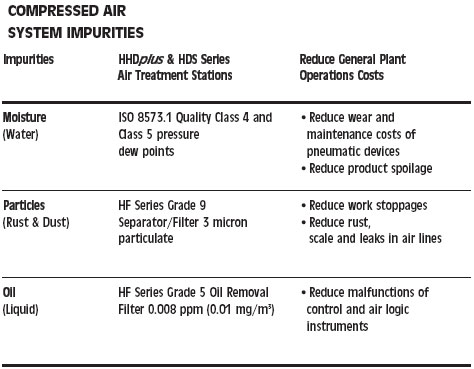

Our mission is to reduce the operating expenditures of compressed air users by removing impurities from their air systems. Utilizing environmentally friendly refrigerants, Hankison ColdWave™ dryers deliver stable ISO8573.1 Quality Class 4 and Class 5 pressure dew points and, remove solid particulates, and oil from compressed air systems across all operating flows.

ISO 8573.1 CLASS 4 AND CLASS 5 DEW POINT SPECIFICATIONS SAVE ENERGY

All compressed air systems must be evaluated individually to develop a specification for compressed air treatment. The majority of compressed air users benefit from Quality Class 4 and Class 5 moisture control due to the low overall cost of operation and low initial purchase price. This technology is ideal for pressure dew point requirements above freezing. Systems with more stringent dew point requirements benefit from desiccant or membrane technologies that offer dew points to ISO8573.1 Quality Class 1.

DEW POINT CONTROL IMPROVES PRODUCTIVITY

At 1700 m3/h, the difference between a 3°C and 16°C pressure dew point can result in 360 l of liquid water going downstream…every week. That is why Hankison strongly recommends high-performance products for maximum contamination removal at the lowest overall operating cost.

DEVELOP AN AIR DEMAND PROFILE TO SAVE ENERGY

Compressed air demand in most plants fluctuates significantly. Hankison offers compressed air users who specify ISO 8573.1 Quality Class 4 and Class 5 pressure dew points, two refrigerated drying technologies to choose from. High performance HHDplus Series and HDS Series dryers include integral 3 micron Grade 9 filtration to deliver high-quality air. Add the integral 0.008 ppm (0.01 mg/m3) w/w Grade 5 Cold Coalescing filtration option to gain premium air quality, simplify installation and benefit from true, Air Treatment Stations. Both optimize energy saving opportunities for various compressed air demand profiles. The chart below will help you determine which solution is best for your application

MATCH AIR DEMAND PROFILES WITH THE OPTIMUM COLDWAVE SOLUTION TO SAVE ENERGY

ColdWave HDS Series, 1500 – 10800 m3/h Energy Saving Air Treatment

• Optimize energy savings for variable air demand profiles that range from 0% to 100% capacity.

• Digital control PLC allows user to track cumulative energy savings.

• Digital Evaporator coupled with an innovative Digital Scroll refrigeration system.

ColdWave HHDplus Series, 211 – 10800 m3/h Continuous Demand Air Treatment

• Rugged reliability and value for steady demand profiles with 75% to 100% total average air flows.

• Energy Management Monitor (emm™) PLC comes with “schedule mode” which turns dryer on and off to optimize energy savings in one or two shift operations. (Models HHDp 381 and larger

MD Series

The next generation in membrane technology

Sıkıştırılmış hava farklı amaçlar ile bir çok farklı alanda kullanılmaktadır. Örnek olarak arabaların lastiklerinin şişirilmesinde kompresörden sağlanan basınçlı hava kullanılır.

Haberin devamı için tıklayınız

İleri - Geri kompresörler, Dönemsel kompresörler, Merkez Kaç kompresörler, Eksenel Akımlı kompresörler, Dönel pozitif yer değiştirmeli kompresörler, Jet kompresörleri, Hidrolik kompresörler, Gaz ve buhar kompresörleri

Haberin devamı için tıklayınız